Products

All

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Featuring a compact mechanical structure and the extensive application of advanced manufacturing technologies. With a single clamping, it can complete peripheral grinding and chamfering over -15° . Equipped as standard with internal on-line grinding wheel dressing, it is suitable for grinding indexable inserts made of various materials.

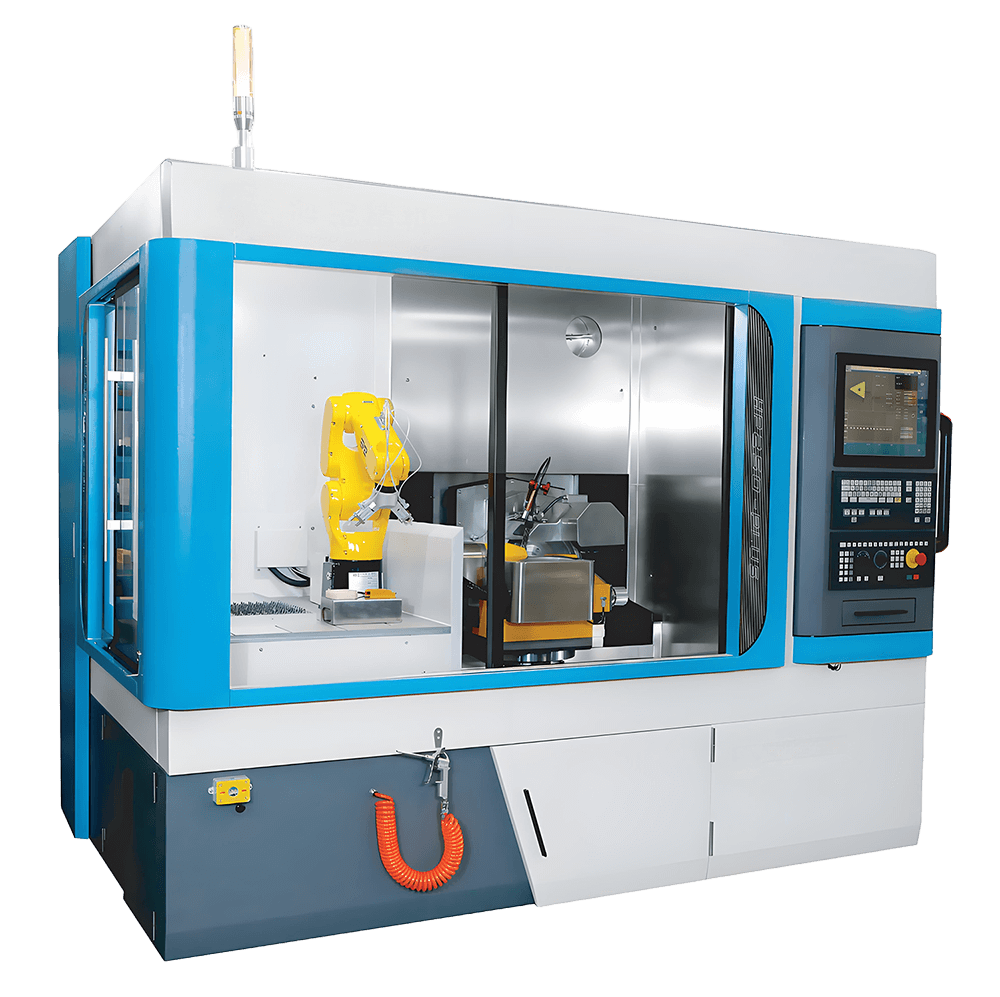

Highly compatible with HP400-PLUS grinding machine fixtures, featuring the same programming mode and user interface as the HP400-PLUS. A single clamping can complete peripheral grinding and single-side chamfering of inserts. The new motion design enables the machining of complex geometries in one clamping.

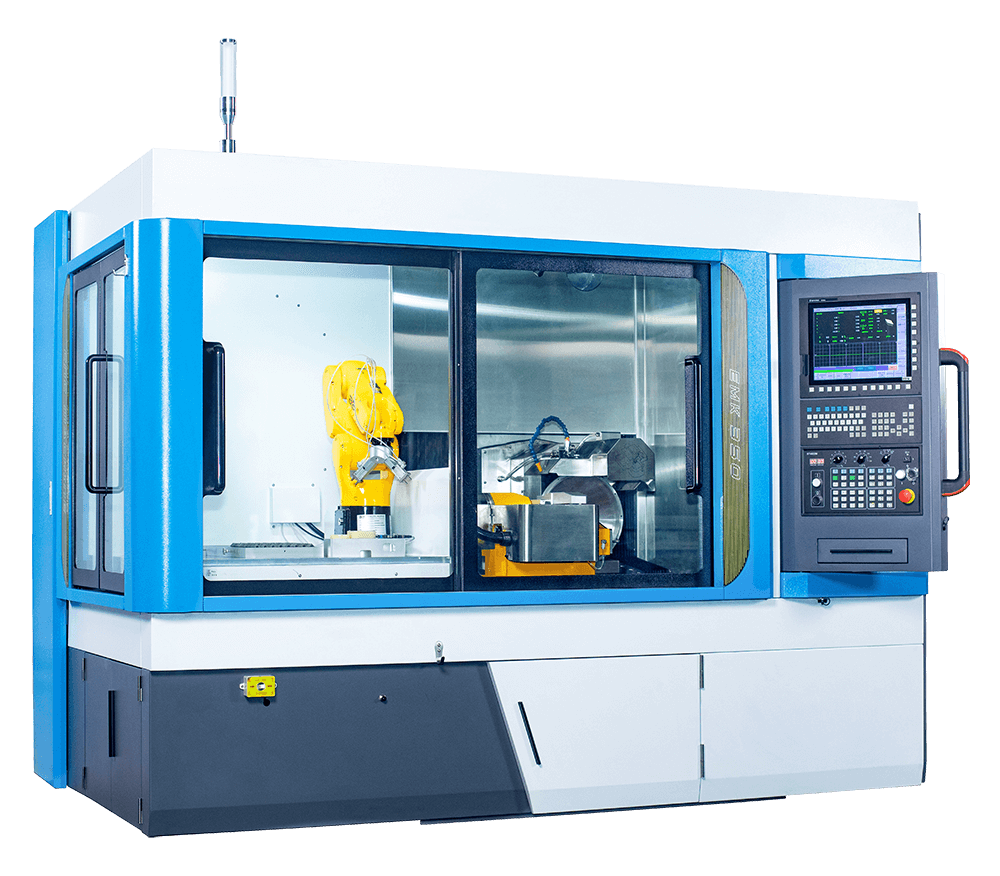

The domestically pioneered four-axis direct drive technology. With a single clamping, it can complete the grinding of K-Lands on both sides. Expanded functionality includes periphery grinding rim of the grinding wheel for grinding special concave arc surfaces.

Featuring a compact structure with a small footprint, delivering high output per unit area. Equipped with a 350mm grinding wheel, it enables periphery grinding and single-sided chamfering in a single setup. Standard with in-process internal wheel dressing, it is suitable for grinding inserts made from various materials. The machine ensures smooth arc transitions and excellent cutting edge quality, making it an ideal tool for mass production.

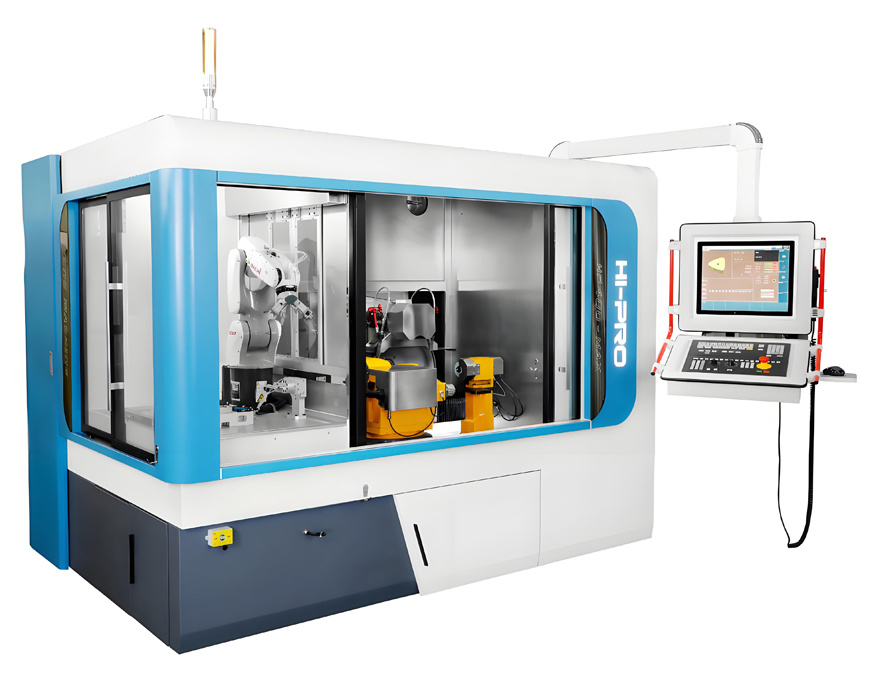

Equipped with a 400mm grinding wheel and features extended Y-axis and C-axis travel. It enables periphery and double-sided chamfering in a single setup. The machine is widely used for processing CNC indexable inserts made of carbide, cermet, ceramic, CBN, and other materials.

Equipped with a 400mm grinding wheel and features extended Y-axis and C-axis travel. It enables periphery and double-sided chamfering in a single setup. The machine is widely used for processing CNC indexable inserts made of carbide, cermet, ceramic, CBN, and other materials.

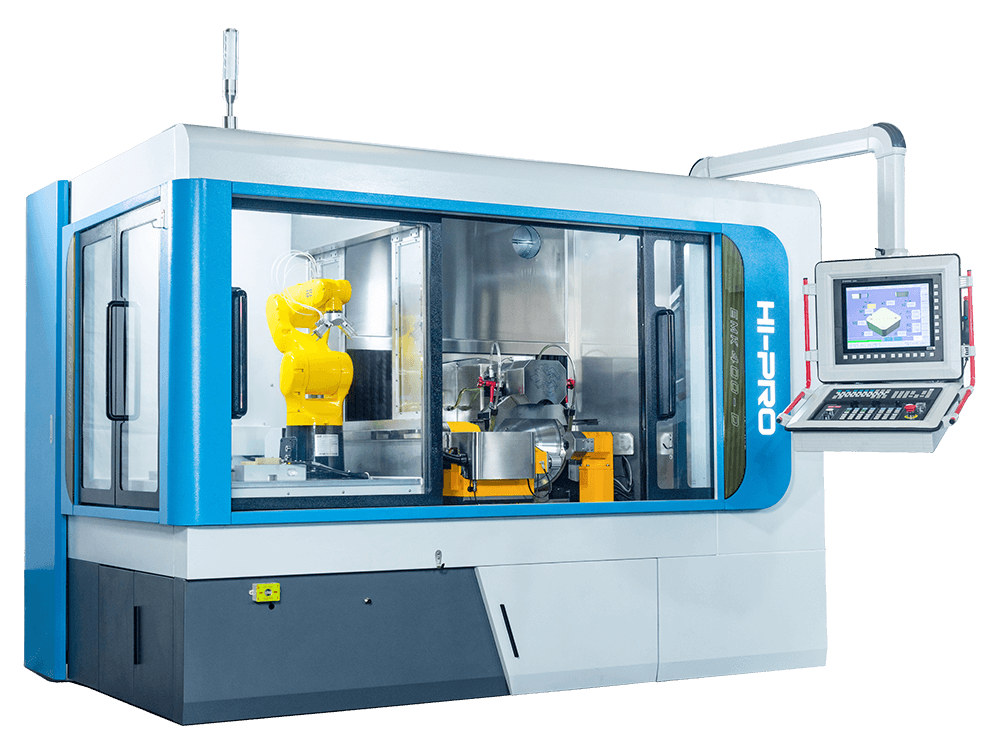

Grinding various grooving inserts, forming inserts, and non-standard inserts by replacing the clamping system. It is also suitable for grinding ISO-standard indexable inserts. A single setup enables simultaneous grinding of the cutting edge,groove, and chamfer. It supports a wide range of materials including carbide, cermet, ceramic, CBN, and PCD. All five feed axes involved in the grinding process adopt closed-loop control to ensure high - precision machining. Equipped with a standard 3D probe, the machine can perform multi - angle measurements on both blanks and finished inserts. The system automatically compensates based on finished part measurements, significantly improving product accuracy.