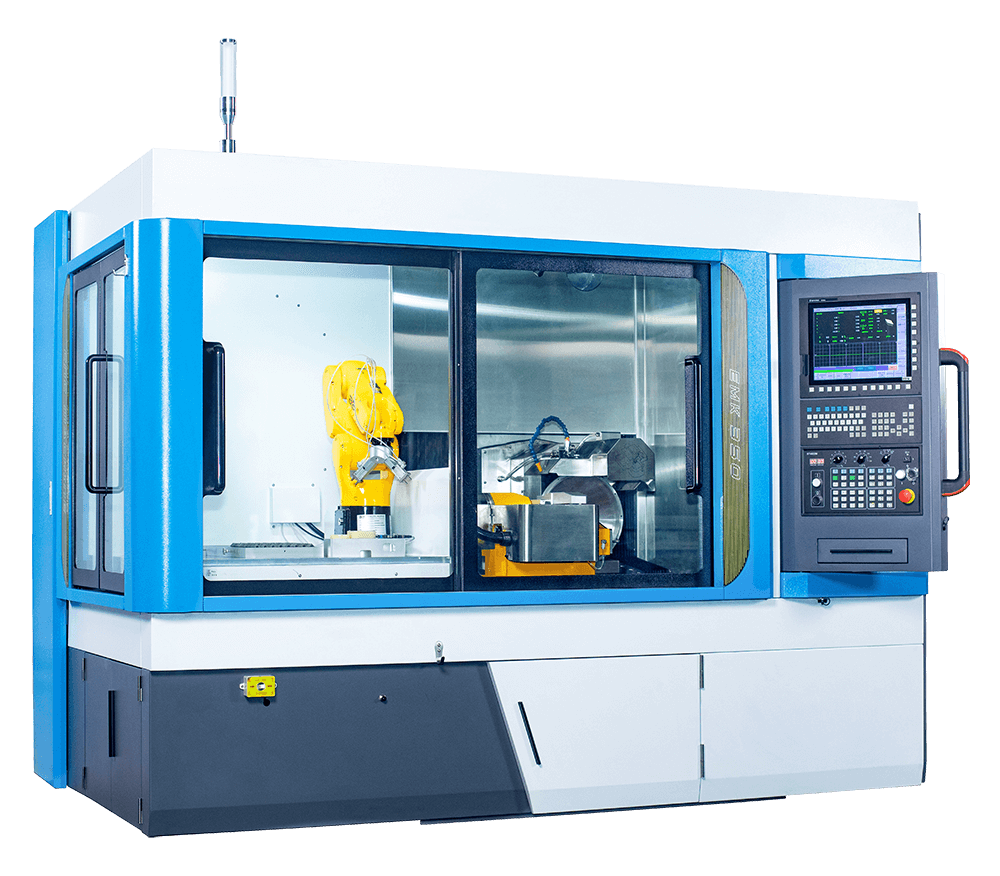

EMK Series - Economical CNC Peripheral Grinding Machine for Indexable Inserts

All

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Featuring a compact structure with a small footprint, delivering high output per unit area. Equipped with a 350mm grinding wheel, it enables periphery grinding and single-sided chamfering in a single setup. Standard with in-process internal wheel dressing, it is suitable for grinding inserts made from various materials. The machine ensures smooth arc transitions and excellent cutting edge quality, making it an ideal tool for mass production.

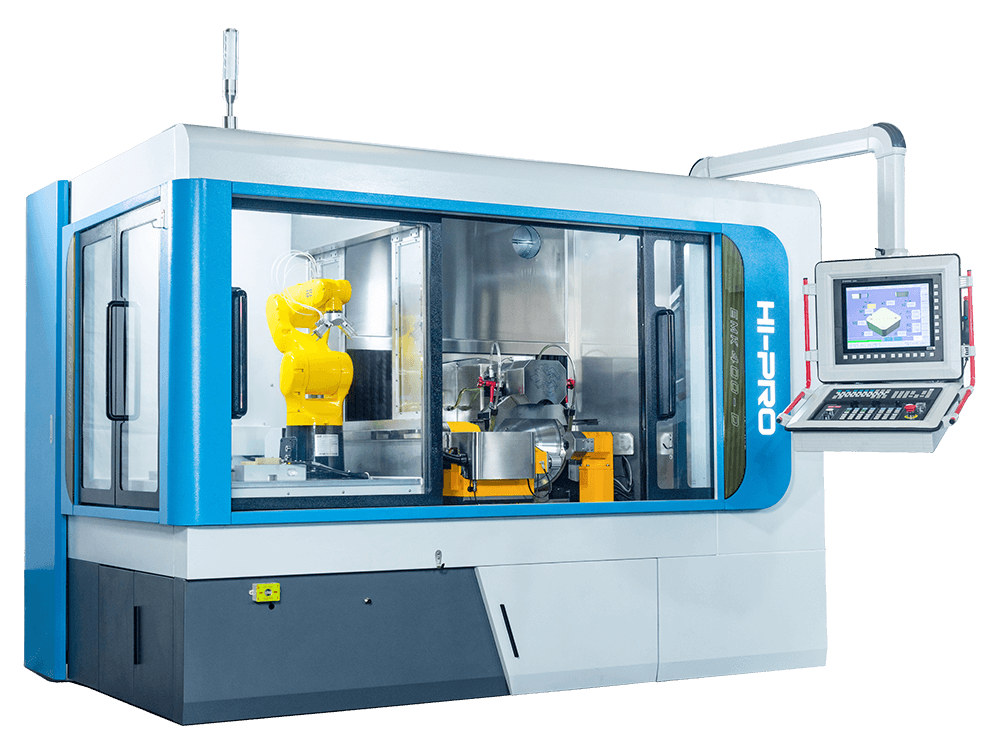

Equipped with a 400mm grinding wheel and features extended Y-axis and C-axis travel. It enables periphery and double-sided chamfering in a single setup. The machine is widely used for processing CNC indexable inserts made of carbide, cermet, ceramic, CBN, and other materials.

Equipped with a 400mm grinding wheel and features extended Y-axis and C-axis travel. It enables periphery and double-sided chamfering in a single setup. The machine is widely used for processing CNC indexable inserts made of carbide, cermet, ceramic, CBN, and other materials.