Technical team from FAGOR visited our company

2025-10-23

Technical team from FAGOR visited our company

On October 16, 2025, the technical team from FAGOR, Spain, visited our company and conducted an in-depth technical exchange and discussion with our technical team.

The HP series CNC indexable insert peripheral grinding machines and the HP250-T five-axis CNC insert grinding centers independently developed and manufactured by Hi-Pro are both equipped with the FAGOR 8070 CNC system from Spain. The 8070 CNC system is built on an industrial-grade Windows platform, offering greater openness and flexibility.

Technical exchange between the two technical teams

Based on the FAGOR CNC system, grinding software upgrade and development

Based on the Spanish FAGOR CNC system, our company has independently developed specialized grinding software for inserts. The software provides a database that integrates all ISO-standard insert parameters. By graphically selecting the geometric parameters of the insert to be machined, adjustments can be made easily and intuitively.

All relevant parameters in the machining process (such as machine settings, grinding process, and auxiliary functions) can be freely redefined through the intelligent control system. Once the parameters are confirmed, the software automatically generates the machining program, which can also be conveniently modified. With a perfectly designed user interface, operators can use the system effortlessly without any professional programming knowledge.

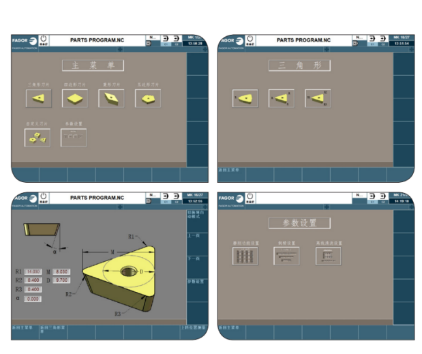

Professional grinding interface

The secondary developed grinding interface displays various data required by the user in a simple and intuitive way, it has a comfortable and sensitive touch screen and interface navigation functions. This allows easy access to different operating modes and minimizes operating steps.

Graphical interactive programming

The graphical interactive programming grinding software provides a database that integrates all ISO-standard insert parameters. Operators only need to input the necessary process parameters to complete the full machining of the insert. Changing insert types and adjusting process parameters can be done quickly and conveniently. The system also features process parameter storage, allowing adjusted parameters to be saved for future use — they can be directly recalled and applied in subsequent machining operations.

Previous:

The next one:

recommend News